Technology

Practical Implementation

The process of biological treatment with biogas production is divided into several stages:

-

Preliminary preparation: separation of larger mechanical impurities (≥ 1,75 mm) in a mechanical sieve.

-

Averaging of effluent parameters in a buffer tank

-

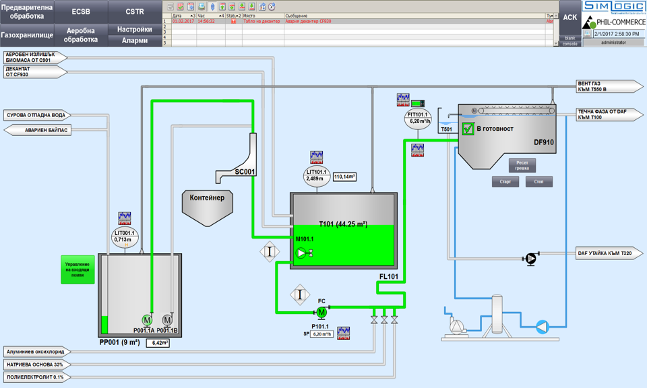

Separation of fats from wastewater, as they are inhibitors and suppress the decomposition process. This function is performed by an aerated flotator (DAF) incl. a pipe flocculator

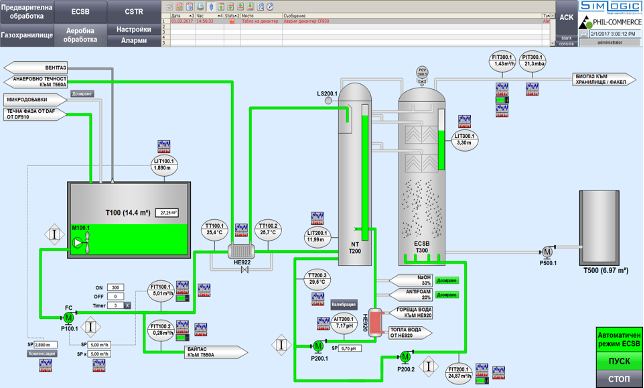

- The liquid phase, after separating the fats, enters anaerobic reactor type ECSB - with built-in 2 phase separators, which retain the anaerobic biomass. The reactor itself is coupled on several levels to an NT neutralization tank where temperature and pH optimization is achieved.

-

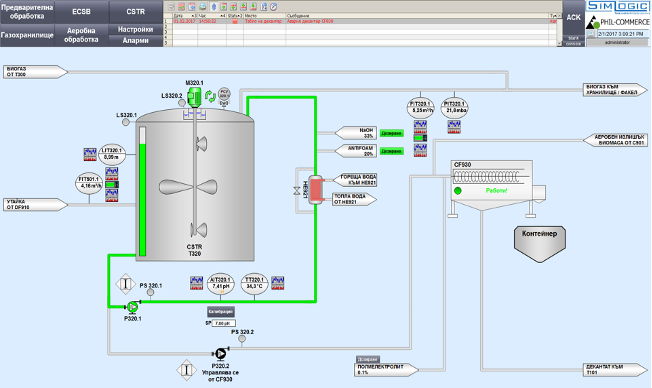

The separated fats and suspended solids are also treated anaerobically, but on an extended cycle (25 days) in a CSTR-type anaerobic reactor.

-

The digested and mineralised CSTR effluent is dewatered in a centrifugal decanter, significantly reducing its volume, and the separated water is directed to the buffer tank of the pre-retreatment

-

In case that a high level of treatment is required, depending on the parameters specified in the discharge permit, subsequent aerobic treatment is needed.

-

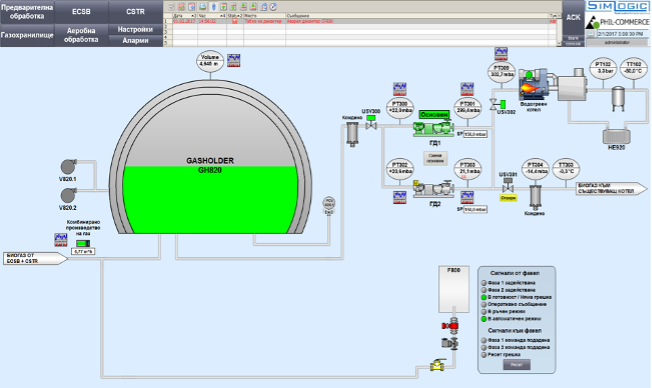

The produced biogas from both the ECSB & CSTR reactors is collected in a gas holder.